ProtoCAM utilizes HP’s Multi Jet Fusion (MJF) technology to produce quality, functional parts at a production speed that is up to 10 times faster than competing processes. Unlike the slower point processes of some other current technologies, MJF 3D printing technology processes parts in two fast area-wide passes to achieve top-speed part production.

The ProtoCAM Distinction

Here at ProtoCAM, we do Multi Jet Fusion differently. Our experienced engineers work with our customers on their unique MJF projects to understand exactly what their goals are and what they would like their end product to be. The ProtoCAM Distinction means that we’re available throughout the entire MJF additive manufacturing process, from initial idea to end product, and we have the capabilities and know-how to guide any project–from prototype to production–to completion.

Your personal project engineer is regularly available to assist you in choosing a material, technology, process, post-processing method, and more, and our friendly customer service representatives can update you on your project timeline, cost, and delivery requirements. Because we’re ISO 9001:2015 certified, you can be assured that your MJF prototypes and parts will be completed according to our high quality standards and produced and delivered to you as quickly as possible, with continuous improvement being a central goal to our facility’s procedures in order to meet our customers’ ever-evolving requirements. Our instant quoting platform means you can order your parts immediately, while our engineer-assisted quoting form allows you to connect further with our engineers on your more in-depth project, and with each order placed, you can be assured that we’re always working towards more sustainable and environmentally-friendly standards of material disposal and recycling, packaging methods, and more.

In offering our Multi Jet Fusion services, we utilize several large-frame systems and quick-cooling stations produced by Hewlett-Packard (HP), which have a build envelope of 16” x 14” x 16″. Our printers can be used to create parts that are intricate and detailed parts, as well as strong and durable, with the ability to utilize multiple post-processing techniques, including dying, smoothing, and more. We also offer a variety of materials for our MJF 3D printing technology, including including PA Nylon 12 and PA Nylon 12 Glass Beads; see our Multi Jet Fusion Material Data list below for more details on all the materials we have available.

Read on to learn all ProtoCAM’s unique Multi Jet Fusion services, or request a quote now to start experiencing the ProtoCAM Distinction for yourself.

What is Multi Jet Fusion

Our MJF printing service reinvents how we prototype and produce functional parts, delivering quality output, up to 10 times faster and at reduced cost.

The process begins by applying a layer of material in a work area. In the opposite direction, in one continuous pass, we print fusing and detailing agents across the full working area. This pass combines the printing with diffusing energy and the process is then completed. HP’s proprietary architecture is capable of printing 30 million drops/second along every single inch of bed width, enabling extreme precision and dimensional accuracy.

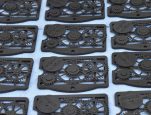

To produce truly functional parts, it’s important to ensure that the material has been properly fused and that part edges are smooth and well-defined. To achieve part quality at speed, HP invented a multi-agent print process. In the time it takes slower point processes, like material extrusion and laser sintering, to build 1,000 parts – MJF 3D printing technology would have created several thousands of parts. Using HP’s proprietary multi-agent printing, the MJF technology achieves new levels of part quality at breakthrough speeds.

In 3D design and printing, a voxel represents a value on a regular grid in a three-dimensional space. By controlling the processes of each individual voxel through agents, MJF can produce parts that can’t be made by other methods.

Though this print style has been compared to selective laser sintering, it works in a completely different way, fusing layers of powder in one pass, while SLS works by sintering each individual part. This means that MJF technology can produce more parts faster, resulting in increased throughput and higher production quantities.

Multi Jet Fusion Tolerances

The technology has a general tolerance of +/- 0.010″ for 1st inch plus +/- 0.002″ for each add inch.

Need to compare technology tolerances? Click here to view our tolerance comparison chart.

Multi Jet Fusion in Action

MJF Case Studies & Blogs

As we produce such a wide variety of products and projects for many different markets and industries using our Multi Jet Fusion technology, we like to showcase all the unique ways MJF can be utilized to create end products and MJF prototypes. Check out some of the below case studies and articles to experience the multi-faceted capabilities inherent with choosing MJF from ProtoCAM!

Production for Protection: How ProtoCAM Helped During the COVID-19 Pandemic

Design for Additive Manufacturing

ProtoCAM’s Environmental Initiatives Program

Automotive Restoration: Producing Legacy Parts for a 1967 Sunbeam

ProtoTip: Continuous Improvement & Consistency via DyeMansion Powershot S

Ensuring the Highest Quality Safety Standards During COVID-19

ProtoCAM Prints 3D Masks for COVID-19 Prevention

ProtoCAM in the Community: Collaborating with the Ed Block Courage Award Foundation

ProtoCAM in the Community: 3D Printing NFL Logos for a Good Cause

Using 3D Printing for Mass Production

Melding Old with New: Recreating Langhorne Carpet Company’s Jacquard Cylinder

Going Green in the 3D Printing Industry

Testing Materials with 3D-Printed Catapults

3D Printing vs Injection Molding – What’s the Best Production Method?

Optimized 3D Production in the 4th Industrial Revolution

ProtoTip: MJF, A Treasure Hunt for Parts

From SLA to MJF: 3D Printing Through the Years

What’s New and Upcoming in HP Multi Jet Fusion

Introducing the HP Multi Jet Fusion

Utilizing MJF During COVID-19

Here at ProtoCAM, when the COVID-19 pandemic first hit, we quickly assessed the situation and made appropriate adjustments to our facility in order to continue operations and protect our staff and customers. Once our facility was secure, we turned to helping others during the pandemic with an initiative to begin developing and producing protective equipment to slow the spread.

As we continued to offer the highest quality service and parts possible, we looked to how we could help others outside of our facility by utilizing our additive manufacturing technologies, as other additive manufacturers around the world were striving to do. In March 2020, ProtoCAM quickly began working to develop and produce 3D-printed masks and other personal protective equipment (PPE) for preventing the spread of COVID-19.

Because of the the desperate need for supplies and particularly protective equipment during the COVID-19 crisis, ProtoCAM began work quickly, while taking all appropriate safety measures, in our attempt to create safe and effective PPE. HP’s Multi Jet Fusion (MJF) technology was chosen to prototype and produce the protective equipment due to the technology’s high production output and material availability, as well as its compatibility with design for additive manufacturing (DFAM) techniques. The PA Nylon 12 material (a non-porous, biocompatible, and skin-safe material) used in the MJF process is biocompatible and can be sterilized, and the technology itself allows for the production of thin-walled features, which helped in the production of effective equipment.

Read our case study to learn more about ProtoCAM’s continued efforts during COVID-19, and how Multi Jet Fusion can assist in creating biocompatible and skin-safe products.

Award-Winning Multi Jet Fusion at ProtoCAM

ProtoCAM’s Multi Jet Fusion additive manufacturing techniques have been recognized for demonstrating exceptional “advanced concepts” in the Technical Competition at the 2018 Additive Manufacturing Users Group (AMUG) Conference. For our submission into the competition, ProtoCAM worked with Langhorne Carpet Company (LCC) to recreate the core of their carpet-manufacturing process: the Jacquard cylinder. After over 80 years in use, LCC’s Jacquard cylinders were beginning to show wear; originally made of extremely rare and environmentally sensitive African hardwood, the Jacquard cylinder is integral to the carpet-weaving process.

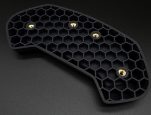

Because of the rare nature of the original part, Langhorne’s initial options for replacing this special piece were limited. Enter ProtoCAM; we took the design and went beyond reverse-engineering the part by making each panel of the cylinder removable and easily replaceable, and adding vents in place of the previously drilled holes. The finished cylinder (printed using HP Multi Jet Fusion 3D printing technology) is significantly lighter than the original, more efficient, and is easily replaceable and replicated. The same design can be used within the other looms throughout the facility as they eventually break down, at which point any minor modifications will be simple to integrate.

Read our case study to learn more about this inspiring and award-winning project from ProtoCAM and Langhorne Carpet Company, and how Multi Jet Fusion can assist in recreating legacy parts via Design for Additive Manufacturing (DFAM) like Langhorne’s Jacquard cylinder.

Why Choose Multi Jet Fusion

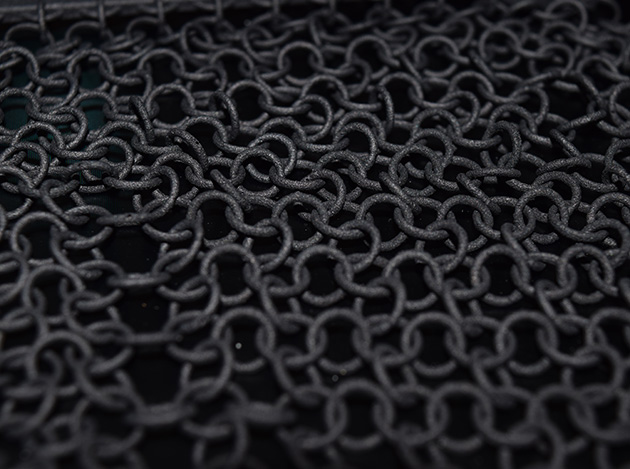

Fine detail and high dimensional accuracy

Get precise small features and detail such as small fine holes, walls and shafts with dimensional accuracy thanks to HP’s unique Multi-Agent printing process.

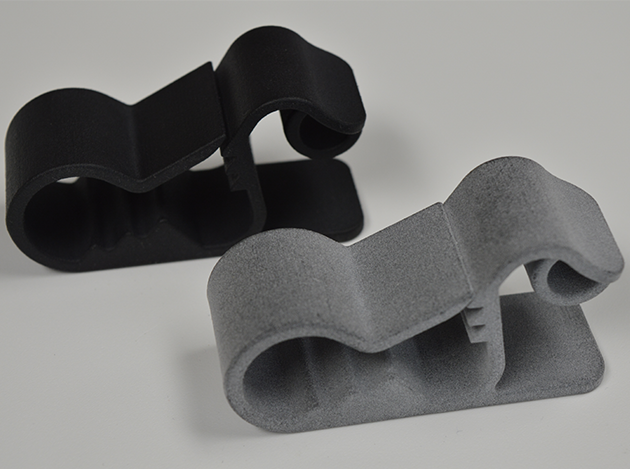

Strong quality parts

Robust thermoplastic that optimizes part quality with cost, producing strong structures.

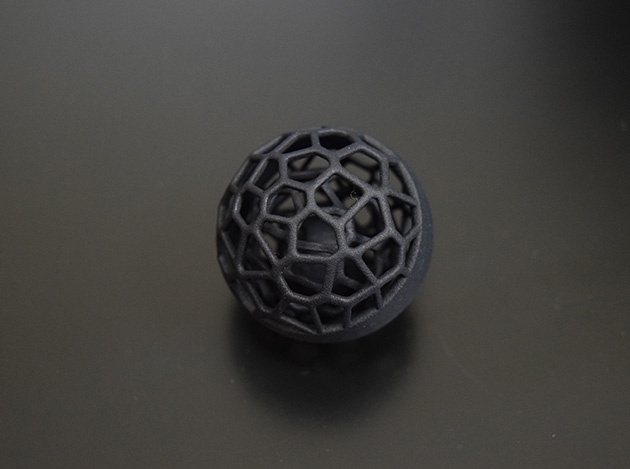

Complex parts and lattice structures

Ideal for complex assemblies, housings, enclosures and connectors.

Typical Multi Jet Fusion Use Cases

| Aesthetic models | Form/fit models | Intricate, detailed parts |

| Larger production quantity jobs | Strong, durable parts |