Wax Casting

ProtoCAM creates wax castings for rapidly-created metal parts. Wax casting can be utilized when multiple metal parts are required quickly, without the need for expensive tooling. This process is typically used for low quantity (10-50) requirements. For less than ten pieces, or for even more rapid turnaround, we recommend checking out our SLA QuickCast service. Wax casting can also be used for low volume production applications where tooling might be expensive and product life cycle may be short, or for high-value, low-volume applications.

The ProtoCAM Distinction

Here at ProtoCAM, we do Wax Casting differently. Our experienced engineers work with our customers on their unique Wax Casting projects to understand exactly what their goals are and what they would like their end product to be. The ProtoCAM Distinction means that we’re available throughout the entire Wax Casting additive manufacturing process, from initial idea to end product, and we have the capabilities and know-how to guide any project–from prototype to production–to completion.

Your personal project engineer is regularly available to assist you in choosing a material, technology, process, post-processing method, and more, and our friendly customer service representatives can update you on your project timeline, cost, and delivery requirements. Because we’re ISO 9001:2015 certified, you can be assured that your Wax Casting prototypes and parts will be completed according to our high quality standards and produced and delivered to you as quickly as possible, with continuous improvement being a central goal to our facility’s procedures in order to meet our customers’ ever-evolving requirements. Our instant quoting platform means you can order your parts immediately, while our engineer-assisted quoting form allows you to connect further with our engineers on your more in-depth project, and with each order placed, you can be assured that we’re always working towards more sustainable and environmentally-friendly standards of material disposal and recycling, packaging methods, and more.

In offering our Wax Casting services, we offer the ability to create parts with reduced or no post-cast machining/processing/tooling required. Wax Casting can also be used for high-value, low-volume applications. When you choose to utilize Wax Castings from ProtoCAM, you choose reduced time to market, high quality techniques, and fast part turn-around.

Read on to learn all ProtoCAM’s unique Wax Casting services, or request a quote now to start experiencing the ProtoCAM Distinction for yourself.

What is Wax Casting?

Wax casting is a process for creating objects, from simple to complex, in a variety of metals by casting an original model or pattern.

To produce our wax castings, ProtoCAM uses stereolithography (SLA) to create a pattern, than produces an RTV (room temperature vulcanization) mold from the pattern. The RTV mold is than utilized to make the wax casting.

After a mold is created, wax casting material is injected into the mold. This allows for near-perfect copies of the original prototype or part to be created. We use vacuum casting technology from Renishaw to produce void-free wax castings.

From the wax casting, metal parts are able to be created. The pattern is dipped in ceramic slurry and then is heated to burn out the wax, creating the cavity used to cast a single metal part. After casting, the ceramic shell is shattered, revealing the part.

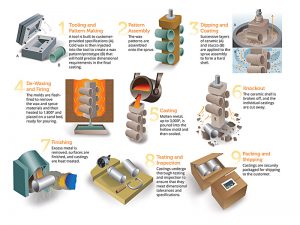

For a visual reference of this process, click the following image to enlarge this graphic from ppcpinc.com:

Wax Casting Case Studies & Blogs

As we produce such a wide variety of products and projects for many different markets and industries using our Wax Casting technology, we like to showcase all the unique ways Wax Casting can be utilized to create end products and Wax Casting prototypes. Check out some of the below case studies to experience the multi-faceted capabilities inherent with choosing Wax Castings from ProtoCAM!

Medical Innovations Made Possible with 3D Printing

From SLA to MJF: 3D Printing Through the Years

Orthopedic Prototype Case Study

Why Choose Wax Casting from ProtoCAM

Accuracy

A high degree of accuracy is maintained in the copy – including the surface finish.

Versatility

Parts without draft, or with undercuts, can be produced.

Speed

Several parts can be created per shift once the mold is complete.

Applications & Industries Compatible with Wax Casting

Wax casting through ProtoCAM can be utilized by any industry, or any customers who requires metal parts for form/fit/function testing quickly and/or in lower quantities. This service is particularly compatible with medical industry applications. Contact ProtoCAM for assistance in determining the how wax casting can be utilized for your unique project.

Wax Casting from ProtoCAM – Key Benefits

- Reduced time to market

- High quality techniques

- Fast part turn-around

- Allows for rapid form/fit/function testing

- Reduced/no post-cast machining/processing/tooling required

- Can be used for high-value, low-volume applications

- Confidentiality of product development is assured

Contact ProtoCAM for Wax Casting Services

ProtoCAM is a leading provider of wax casting services. Please contact us for more information on our wax casting services or to request a quote.