Industrial Prototyping & Production Using 3D Printing and Additive Manufacturing

ProtoCAM specializes in industrial rapid prototyping and 3D printing/additive manufacturing for industrial applications. Past industrial projects we’ve helped bring to life include parts & prototypes, industrial components, and physical prototypes for industrial applications. ProtoCAM has produced industrial prototypes for many major industrial manufacturers and their suppliers, including valves, pumps, gears, bearings, and hydraulic equipment. Our vast experience in rapid prototyping and production for industrial applications makes ProtoCAM the clear choice for industrial projects.

Examples of Industrial Rapid Prototypes and Parts

ProtoCAM’s customers have used our rapid prototyping services and 3D printing/additive manufacturing capabilities to create a wide variety of industrial parts, both small and large, and in a variety of different materials. Our customers include manufacturers and designers of tractors, valves, pumps, lifts, trucks, robotics, custom assembly equipment, and many more. Examples of our industrial work include:

- Robotics parts

- Controllers

- Hydraulic lifts

- Pump parts and components

- Casings

- Sprinklers

- Part castings

- Engine parts

- Mechanical parts

- Pneumatic parts

Industrial Prototypes and Parts from ProtoCAM – Key Benefits

- Reduced design time and cost

- Reduced testing time and cost

- Fast part turn-around and delivery

- Better visualization of products with the creation of a physical, solid, tactile item in addition to drawings and computer models

- Testing can be conducted based on form, fit, and function

- Quick iterative testing is possible

- Wide variety of available prototype and production materials available

- Confidentiality of product development assured

ProtoCAM Industrial Case Study

ProtoCAM Industrial Case Study

![]() ProtoCAM Industrial Case Study

ProtoCAM Industrial Case Study

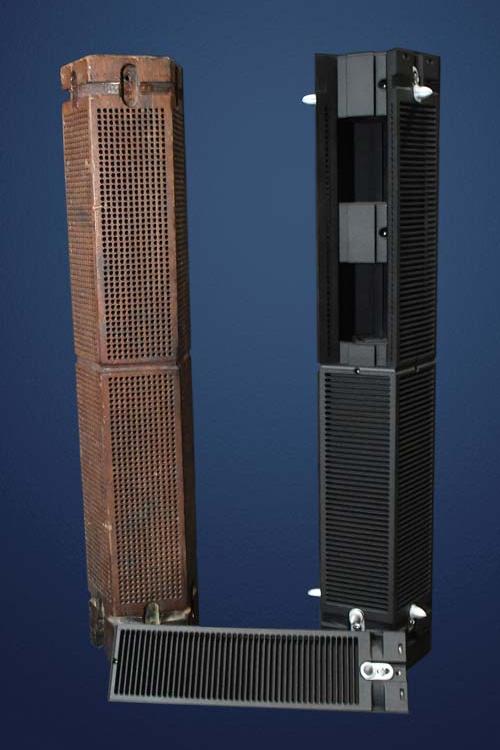

ProtoCAM worked with Langhorne Carpet Company to replace their Jacquard cylinder–the core of their carpet-manufacturing process.

Originally made of extremely rare and environmentally sensitive African hardwood, the Jacquard cylinder is integral to the carpet-weaving process. After over 80 years of use, Langhorne Carpet Company’s Jacquard cylinder needed to be replaced. ProtoCAM was able to help re-design and reverse-engineer the cylinder, and replace it with a new, improved, 3D-printed part.

This innovative project won first place in the “advanced concepts” category of the Technical Competition at the 2018 Additive Manufacturing Users Group (AMUG) Conference.

Read our case study for more details:

Melding Old with New: Recreating Langhorne Carpet Company’s Jacquard Cylinder.

Materials Used in Industrial Prototyping

- Aluminum

- Stainless steel

- Brass

- Bronze

- Carbon steel

- HT steel 4140

- Zamac (Zinc/Aluminum)

- Silicone rubber

- Urethane

- Epoxy

- Thermoplastics

Contact ProtoCAM for additional material offerings for industrial applications.

Industrial Prototyping and Production

3D printing and additive manufacturing technologies are proven technologies for use in industrial applications, and are quite often utilized by engineers and designers of industrial parts. This technology is utilized to create physical, tangible prototypes and parts for use in design work, testing, and end-use applications.

The design process for new or improved industrial parts and components includes producing, examining, and testing a physical prototype to check its performance and look for improvements. Prototypes are most often been used for iterative testing, but with rapid prototyping and production, this process can be completed faster, more efficiently, and at a lower cost. Engineers and designers benefit from having an industrial prototype to confirm that the size, shape, fit, and function are correct, and any needed changes can be completed before production begins.

Along with prototype production, ProtoCAM brings manufacturing and engineering expertise to the end-use production of industrial parts. ProtoCAM’s experienced engineers provide valuable insight to help improve designs and create parts that are easier and less costly to manufacture. Additionally, prototyping and production for industrial applications is not limited to small parts; multiple components can be joined to create very large products.

3D printing and additive manufacturing technologies can be used for producing parts for many industrial applications, as ProtoCAM has demonstrated by utilized various additive manufacturing and 3D printing processes to create industrial parts for many major industrial manufacturers. Contact us today or request a quote to learn more about how our additive manufacturing services can be applied to your industrial project.

Contact ProtoCAM for more information on industrial prototypes and 3D printing/additive manufacturing for industrial applications.

Click here to get a quote for industrial rapid prototyping and 3D printing/additive manufacturing services.