Also known as metal 3D printing, the direct metal laser sintering (“DMLS”) process involves the fusing of powdered metals with an infrared laser beam. This allows for the creation of metal prototypes and production pieces with no special tooling and rapid turnaround times.

What is Direct Metal Laser Sintering

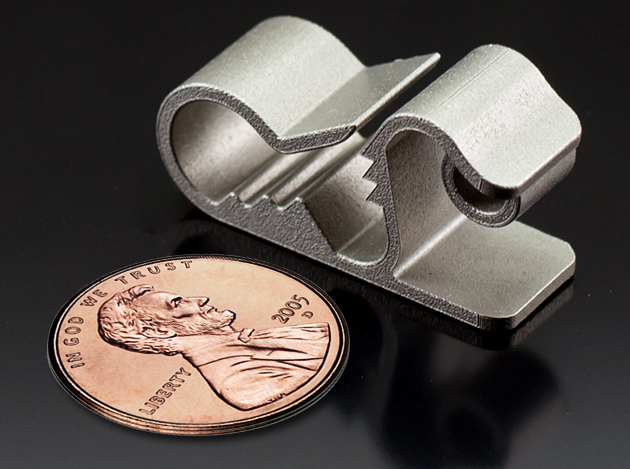

Direct metal laser sintering (DMLS) is an ideal rapid prototyping solution for customers that need high-quality 3D metal parts or metal prototypes quickly. Although DMLS typically costs more than other rapid prototyping techniques, no special tooling is required, allowing for turnaround times of 2-4 weeks. This process is typically used for highly complex, intricate metal prototyping and production that would be difficult or impossible to produce with traditional methods.

In DMLS, 3D metal parts are created by fusing, or sintering, powdered metals with the heat from an infrared laser beam. Similar to selective laser sintering (SLS), metal layers are repeatedly laser sintered, creating the desired three-dimensional piece based on a 3D CAD model or STL file. There are multiple metal materials available for DMLS, including aluminum, cobalt chrome, maraging steel, nickel alloy 625, nickel alloy 718, stainless steel, and titanium.

Direct Metal Laser Sintering in Action

Why Choose Direct Metal Laser Sintering

Homogenous Materials

DMLS metal 3D printing uses homogenous materials, minimizing potential complications.

Easily finished

Parts produced using DMLS metal 3D printing can easily be machined, EDM processed, polished, etched, textured and more.

Variety of material options

Parts can be produced using a variety of material types.

Typical Direct Metal Laser Sintering Use Cases

| Small-batch manufacturing | Simulated investment-cast parts | Temperature-resistant pieces |

| Machinable parts | Functional prototypes |