How Additive Manufacturing Suits Any Type of Medical Device

Additive manufacturing is the ideal way to create medical products. A variety of production processes allow you to design parts with internal tubes, channels, curves, and other features that are impossible to create with traditional machining or molding.

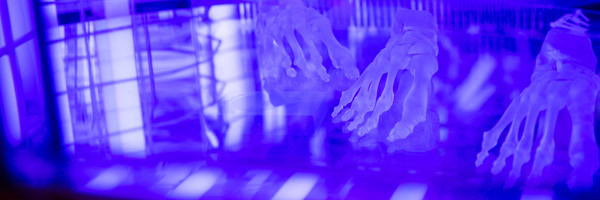

Additive manufacturing makes it easy to create complex natural shapes using advanced medical-grade plastics.

Prototypes for Health and Life Sciences

You need to bring your lifesaving vision into the world as quickly as possible. We’ll help you every step of the way, from the first prototype, through testing and iteration, and on to the show-ready finished product, and even short-run production.

We offer all types of finishing services so your device looks its best, including proprietary finishing techniques for crystal-clear plastic parts.

Specializing in:

- Medical models and displays

- Component parts

- Catheters

- Stents

- Fluid administration systems

- Drug delivery systems

- Chemotherapy tips

- Syringes

- Cardiovascular devices

- Vascular access devices

- Ergonomic instruments

- New innovations

If you have an idea but no drawings, that’s fine—we can suggest a number of top notch designers to help you create your 3D CAD model. They can help with the drawing and planning needed to speed up the process so we can make your part as you need it.

The case study below shows ProtoCAM’s rapid prototyping team in action:

Case Study: Rapid Prototyping of Medical Devices

The customer needed to quickly create a handheld device for medical testing. Speed was essential: the product would be used for scientific testing on NASA’s space shuttle flights, and NASA’s production timeline was non-negotiable. ProtoCAM had to speed up both the design and production of the product.

By drawing on years of experience, ProtoCAM’s engineers improved on the customer’s excellent initial design. We reinforced the product’s internal support structure, enhanced its ergonomics, and slightly increased the wall thickness to avoid sink indentations during molding. Together, these improvements created a stronger piece that was easier and less costly to manufacture.

The product was ready to go into production only days after we received the design. ProtoCAM’s start-to-finish capabilities sped the product through the approval process, from prototype to testing, and then to tooling and injection molding. The entire project was completed in less than five weeks, on schedule. The device was successfully used for microbiological testing at NASA’s Marshall Space Flight Center and on NASA’s space shuttle.

ProtoCAM has been making medical device prototypes for over twenty years, serving the world’s largest medical device manufacturers. Our vast experience in all phases of prototype design and development ensure the success of your product.

Physical/Anatomical Parts

There’s no limit to the variation of the human body. Physical and anatomical parts need to fit any body type, and there can be many ways to produce each part. We’ll help you choose the best manufacturing process by drawing on our years of medical manufacturing experience.

If you’re making a prototype, we’ll help you get the highest level of detail while keeping your project affordable. If something else is your top priority—strength, flexibility, or friction, for example—we’ll deliver the performance you demand. ProtoCAM excels at creating implants, including augmentations, replacements, prostheses, and new innovations.

Medical Models

Medical models have been learning tools for years, and additive manufacturing offers a new level of customized learning and training devices. Practitioners can rapidly create models to visualize emerging conditions or even single-case scenarios. Using images from your MRI or CT scans, ProtoCAM can quickly produce three-dimensional medical models.

Additive manufacturing is ideal for complex models, especially shoulders, hips, knees, and other joints. Use ProtoCAM’s models to plan more efficient surgeries, explain procedures to patients, or train the next generation of doctors. These models are also ideal for forensic analysis, research and development, and medical device sales.

With ProtoCAM, you get a fast turnaround and total confidentiality. Choose from silicon rubber, urethane, epoxy, or any USP-approved medical grade material. If you need specialty materials, just ask—we know where to find them.

Contact us to create your superior medical devices.

When you need precision plastic parts for medical applications, choose ProtoCAM. We specialize in medical devices, physical/anatomical parts, medical models, and more. Whether you need prototypes, customized devices, or mass-production elements, ProtoCAM will deliver the parts you and your customers can depend on.