How Additive Manufacturing Can Benefit Local On-Demand Manufacturers

Outsourced additive manufacturing offers big benefits for local on-demand manufacturers, including faster production, a broader range of products, lower inventory costs, happier local customers.

Read on to find out how!

What is on-demand manufacturing?

On-demand manufacturing is a process where a customer order can be immediately fulfilled with a custom-manufactured product. Traditional manufacturing allows a defined range of items to be manufactured on-demand, based on preset tooling and raw material inventory. In contrast, additive manufacturing allows a near-unlimited range of products to be manufactured on-demand.

A broader range of products

With additive manufacturing, you (a local manufacturer) can make a wider variety of on-demand products than you could with traditionally outsourced manufacturing. This potential variety is possible because every project is built up from a clean slate using universal raw material.

It’s typically considered a challenge to offer on-demand manufacturing using traditional manufacturing models. The range of products you can offer on-demand is constrained by your setup budget. You’ll need to have any necessary tooling and production configurations defined up-front. If not, the best you can offer is an accelerated manufacturing timeline, where you rush through setup and tooling, and hope customers don’t notice that production is not truly on-demand.

You don’t have to guess what the market wants

With traditional manufacturing, you need an inventory of raw material on-hand in order to fulfill orders immediately. Ideally, these raw materials are already cut to size for their intended products. It can be expensive to carry this inventory, and it’s a gamble on the market’s demand.

Additive manufacturing is a safer route because products are built up from raw material, not sculpted down. There’s no need to store specialized pre-cut blocks or other prepared materials.

Additive manufacturing also uses a more universal form of raw material. Even if there’s a surplus of raw material, its universal appeal (versus larger, specialized shapes) means that excess stock finds a ready market—it can be sold faster to other manufacturers at a higher price.

Either way, when you work with a manufacturing partner, you don’t carry the raw material inventory—they do.

Less setup leads to faster production

Your additive manufacturing partner can make your product using just a computerized design file and in-stock raw material. Other manufacturing methods require longer lead time to set up, which can translate into greater expenses for you and the end customer.

For example, CNC machining requires not just computerized instructions, but also a specialized cutting tool, a chunk of raw material that’s been properly cut, and often more. Because additive manufacturing “builds up from nothing”, it’s easier to get started fast and with little to no lead time.

The elimination of a need for tooling enables additive manufacturing to deliver one of it’s biggest advantages- design changes require no additional time or expense for tooling modifications.

A collaborative production relationship

Because of the lower setup costs mentioned above, working with an additive manufacturing partner makes it easy to offer on-demand production of multiple iterations of a product. This can be a hugely valuable service to a customer who is trying to lock down a final design. It brings the benefits of on-demand manufacturing to the prototyping process.

Keeping local customers happy

Many local on-demand manufacturers tend to serve customers in a specific region to provide faster delivery times and lower transportation costs. Their local presence also means they get more “emergency jobs” such as urgent repairs and replacements. This may be true of your business, too.

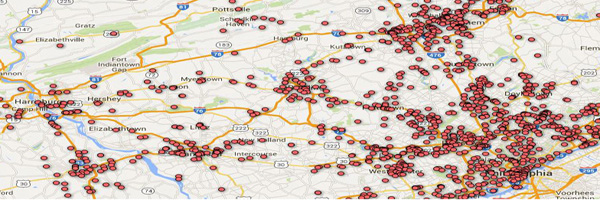

Partnering with a local additive manufacturing company helps local manufacturers amplify their strengths. They can fulfill a wider variety of requests compared to what they could make if they produced in-house. They can also produce and ship just as fast as if they manufactured on-site, because their additive manufacturing partner is nearby.

If a customer chooses you because you’re only 30 miles away, and your additive manufacturing partner is six miles away, the customer still gets the local benefit they expect. A customer who makes a local purchase request only to find out the “local partner” shipped the job across the country—or overseas—would have reason to be quite upset. Local manufacturing partners keep your local customers happy!

ProtoCAM has over two decades’ experience providing additive manufacturing on-demand. If you need on-demand additive manufacturing, request a quote here or send us a message.