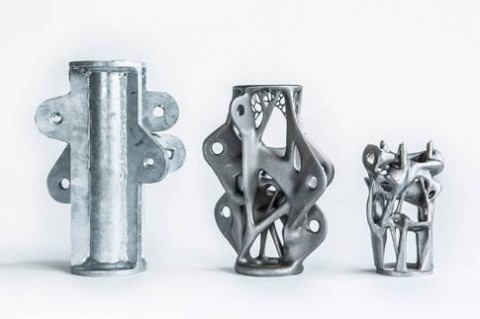

Traditional manufacturing vs additive manufacturing in creating structural elements (source: arup.com)

Infinite Innovations with Additive Manufacturing

Additive manufacturing offers several benefits over traditional manufacturing. With additive manufacturing, you will:

Save Time

By utilizing additive manufacturing, you can get to market quicker by avoiding wasting valuable time waiting for retooling. If reworking the design is necessary, adjustments can simply be made to the CAD file and programmed into the 3D printer. And since an engineer at ProtoCAM can get you a quote in as little as two business hours, your time to market is reduced even further!

Conserve Money

Because retooling is unnecessary, you avoid having to pay for the costly changes to an assembly line that retooling can require. This means that you can order a single 3D prototype at a fraction of what it would cost using traditional manufacturing. Plus at ProtoCAM, your price per object only decreases with each additional item ordered per print!

Reduce Waste

Unlike traditional manufacturing methods which can result in lots of waste that may not be correctly recycled, the only material that is consumed via additive manufacturing is the actual material used for the end-product. At ProtoCAM, we’re always looking for new ways to make our manufacturing and shipping process “greener,” which includes introducing products like Expandos, which are a recycled cardboard material we use instead of packing peanuts.

Produce Innovation

With additive manufacturing, you gain the ability to make parts that simply can’t be produced by traditional means. Parts can be printed with multiple integrated components, made to perfectly fit together with other 3D printed projects, and include gradients of color. Advances in 3D printable materials means that the industry can now print in countless new materials, among the more traditional resin and metal materials. The result is that beautiful, complex, and durable end products can be produced through industrial additive manufacturing. Combine that with the advanced finishing processes offered at ProtoCAM, and your perfectly rendered additive manufactured part will be presentation-ready at a fraction of the time, cost, and waste of traditional manufacturing.

So what are you waiting for? Request a quote for your additive manufacturing project today!