With over 25 years of additive manufacturing experience, ProtoCAM offers a wide variety of rapid prototyping, production, manufacturing, 3D printing, and post-processing services. Whether you need an attractive presentation model, a durable piece for product performance testing, or even a metal piece, our experienced team of engineers can help you get exactly what you need – fast.

About Additive Manufacturing

ProtoCAM has long been synonymous with great additive manufacturing (also called “direct digital manufacturing”). We serve the additive manufacturing needs of customers both large and small.

Prototyping is used for making parts (product prototypes) for the design or testing phase of product development and creation. Additive manufacturing (also called direct digital manufacturing) takes this one step further, creating a finished product that is ready for use by the end user. Typically, additive manufacturing consists of a shorter production run – from a single piece, to a few hundred items. What is additive manufacturing?

Additive manufacturing is a relatively new concept, made possible by vast improvements in the resins and materials utilized in the available processes. Until recently, a stereolithography prototype would not have been suitable for use as a finished product; though the fit and finish would have been correct, durability would have been lacking.

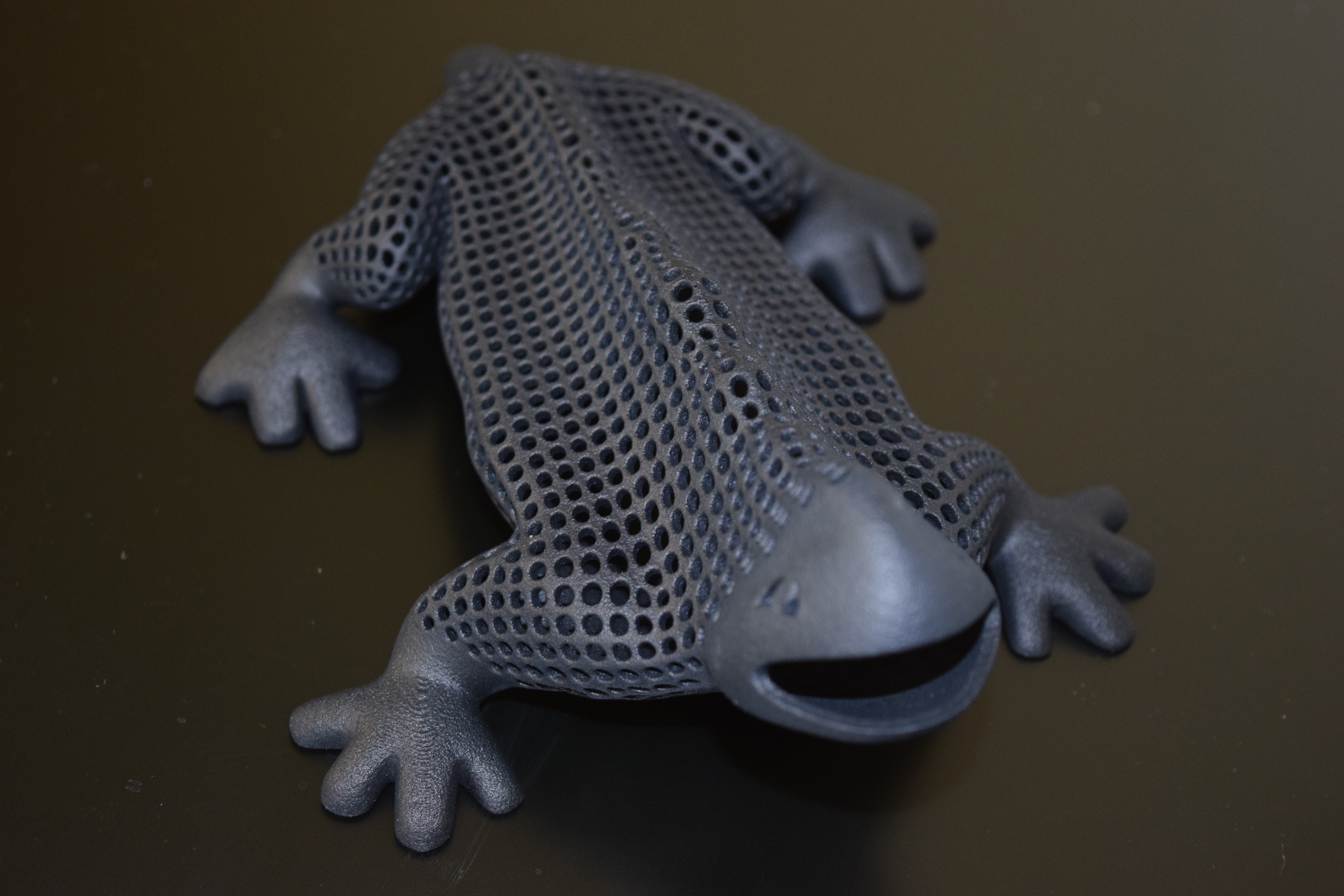

Fortunately, the resins used in additive manufacturing today allow for the creation of fully-functional items that can be used immediately, and can endure the test of time. This means additive manufacturing has become a viable method for creating finished goods. And because those resins and materials are always improving, ProtoCAM can and does regularly create an ever-growing variety of items using our specialized additive manufacturing techniques.

Why use ProtoCAM for your additive manufacturing project?

ProtoCAM’s extensive experience, spanning over two decades in the additive manufacturing industry, makes us the ideal partner. We specialize in creating market-ready items directly from 3D CAD models, allowing for:

- Zero or near-zero tooling costs, which are usually rather high with other production methods

- Low production cost overhead

- Vastly increased production speed

- Vastly decreased time to market

At ProtoCAM, we have the experience necessary to guide our customers towards utilizing the ideal equipment and material for their unique project. Our in-depth knowledge of our echnologies allows our engineers to recommend which process will work best for your specialized requirements. With a wide variety of in-house technologies, materials, and services, ProtoCAM serves as your one-stop shot for all your additive manufacturing needs.

What is a good project for additive manufacturing?

A typical item that ProtoCAM can create with additive manufacturing might have several of these characteristics:

- Small size, or the ability to be created in pieces and built together

- Low to medium quantity

- Previously made with low volume injection molding, epoxy, or aluminum tooling

- Limited product life span (life span is longer in the cases of some materials and print styles)

- Defined quantities needed

- Geometry that cannot easily be made using traditional manufacturing methods

Ready to request a quote for your additive manufacturing project? Click here.