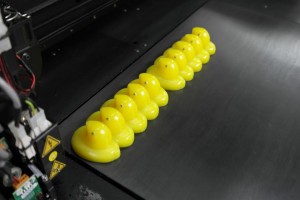

Bethlehem candy company Just Born, Inc., maker of the iconic PEEPS® line, is exacting when it comes to manufacturing their original chick-shape marshmallow candy. To keep the production line running smoothly and turn out flawless product, they approached ProtoCAM to produce an internal conformity sample of a 5-chick PEEPS® cluster.

They wanted a prototype they could use on the production floor that represented the exact shape of the ideal PEEPS® chick cluster, but they had very little experience with additive manufacturing and no idea what their options were.

Rather than starting with a design file, this project would start with an actual product that needed to be accurately scanned into a CAD file to drive the additive manufacturing process. Just Born had considered a number of additive manufacturing companies in the past but felt ProtoCAM was the best fit.

A Team Effort

“ProtoCAM had the capabilities when it came to technologies and turn around time, but also a depth of knowledge, and solid reputation,” said Nicole Grande, Graphic Design Technician. “We also knew we were going to have to educate ourselves about the industry and ProtoCAM was willing to work with us as an integrated team rather than simply a vendor.”

“ProtoCAM had the capabilities when it came to technologies and turn around time, but also a depth of knowledge, and solid reputation,” said Nicole Grande, Graphic Design Technician. “We also knew we were going to have to educate ourselves about the industry and ProtoCAM was willing to work with us as an integrated team rather than simply a vendor.”

The fact that ProtoCAM was located just a few miles from Just Born’s world headquarters didn’t hurt either. After initial conversations about the specific goals of the project, the Just Born team made a trip out to the ProtoCAM facility to see the processes, sample products and fully understand all their potential options.

Just Born wanted to be sure they would be getting enough detail from the initial scan and then from the prototype to use the piece for a quality control reference. The prototype also needed to be sturdy enough to be handled.

“You can talk about a substrate all you want, but to actually see it and touch it in person is really helpful,” Grande said. “And we had a lot of questions. Specifically, if we gave them a cluster how representative would the scan really be and how much could we manipulate the file before printing?”

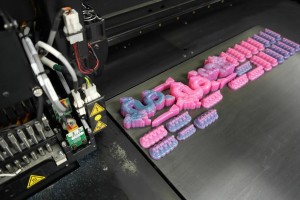

The ProtoCAM engineers worked closely with the Just Born team to determine the very best method and material for the project, finally landing on PolyJet 3D Printing.

The ability to blend materials with PolyJet meant the final prototype could be both durable enough to withstand regular handling and flexible enough so if it were dropped on the production floor it wouldn’t shatter or break. It also meant ProtoCAM could deliver detail, durability, speed and exceptional color in a single step and at the right price point for Just Born’s single-part print-run.

Delivering More Than A Prototype

For ProtoCAM, an educated customer is a return customer and, in the end, Just Born didn’t just get a prototype, they got a partner. ProtoCAM’s obsessive commitment to service fulfilled Just Born’s corporate curiosity and enabled them to easily understand how additive manufacturing could be leveraged beyond this singular project.

When ProtoCAM engineers personally delivered the first printed PEEPS® prototype to the Just Born offices for a one-on-one reveal, Grande and Rich Milker, Vice President of Technical Services, were already looking ahead to future possibilities.

“The value of the PEEPS® prototype project goes well beyond just this one piece,” Grande said. “We’re evaluating how we can utilize the capabilities in other areas of the company. The simple ability to shrink a prototype down to as small as one-inch or enlarge an exact replica of a product at will could have significant benefits for our retail group’s R&D process.”

“The value of the PEEPS® prototype project goes well beyond just this one piece,” Grande said. “We’re evaluating how we can utilize the capabilities in other areas of the company. The simple ability to shrink a prototype down to as small as one-inch or enlarge an exact replica of a product at will could have significant benefits for our retail group’s R&D process.”

To that end, Just Born asked ProtoCAM to present a workshop on modern additive manufacturing to more than 35 team members explaining the process, outlining how the technology has been used by corporations worldwide, and postulating how Just Born might apply it elsewhere to the benefit of business as a whole.

“In addition to working with us to build a great prototype, ProtoCAM was more than happy to help Just Born build our corporate knowledge based,” Grande said. “From concept through completion the engineers were always available to field our questions or concerns, and turnaround time exceeded expectations. It was the personal touches that really turned what could have been a one-off project into a really positive business relationship.”

PEEPS®, and the PEEPS® chick and bunny shapes are registered trademarks of Just Born, Inc., Bethlehem, PA © 2015. All Rights Reserved.