Using Industrial 3D Printing to Reduce Manufacturers’ Unplanned Downtime

Production breakdowns can cost manufacturers thousands of dollars each minute, so savvy companies use 3D printing to reduce their unplanned downtime.

Here are a few ways you can apply the benefits of additive manufacturing (industrial 3D printing) to improve your operations:

AM: A fast, low-cost way to get replacement parts

Traditionally, replacement parts come from the original equipment manufacturer (OEM). Unfortunately, OEMs often stop making replacement parts at arbitrary times — maybe due to cost cutting, new strategies, or as part of a planned obsolescence program.

When an OEM stops making parts, the next source is typically a secondary manufacturer like a metal stamping company, injection molder, or machine shop. These specialty orders often have quantity minimums — you’ll need to buy parts in bulk or pay extra for tooling and setup.

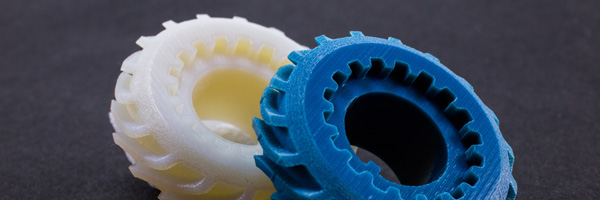

With additive manufacturing, you can purchase small quantities of replacement parts at an overall lower price. There’s no mold-making or tooling to worry about. Your local additive manufacturing partner can take your sample part — oftentimes even if it’s broken — and recreate the part you need.

Only stock what you require

When traditional replacement parts are ordered in bulk, the oversized purchase clogs up your inventory area. This is not the case with 3D printed parts. Most additive manufacturing shops have no minimum quantity. So even though the price-per-part tends to be slightly higher with 3D printing, your overall cost is lower because you only need to stock a handful of parts.

Store a greater variety of replacement parts on-site

AM’s lower quantities per order make it feasible to stock a greater variety of replacement parts at your facility. Now you don’t have to gamble on which parts are most likely to fail, hardest to find, or slowest to ship. You can keep a small stock of hundreds of parts on-site thanks to additive manufacturing — something that would be impossible using expensive traditional manufacturing with high minimum orders.

Faster delivery of replacement parts

When you don’t have a replacement part on-site, additive manufacturing can get it to you faster than traditional manufacturing. The odds are low of finding a traditional shop nearby who can deliver your replacement part fast. But because additive manufacturing doesn’t require any setup to make your replacement, a nearby shop can deliver the part you need. Delivery times often range from days to mere hours for an emergency situation.

Partner with a local AM shop for better parts

Your local additive manufacturing shop can even improve on OEM parts. Specialists can see how and why the part failed, and make improvements to increase the life of the replacement. For example, the AM partner can recommend a stronger material, a more flexible material, or a lower-friction material.

Keep old machines running longer

With additive manufacturing, there’s no need to consider replacing old machines due to a shortage of replacement parts. This will help you save money, or allow you to divert capital and hard-earned credit to more efficient uses.

Replace parts as you need them

Today, 3D printed parts keep production lines running for the world’s top manufacturers. Parts don’t break in bulk — so there’s no reason why you the manufacturer should be expected to buy replacement parts in bulk. When old, out-of-production parts need to be replaced fast, additive manufacturing is a natural solution.

ProtoCAM has worked with manufacturers for over two decades to reduce unplanned downtime. We’re here when you need a replacement part made fast — contact us anytime, with or without the part you need. We know how to create replacements even if the original is gone.

If you want to talk about building an inventory of replacement parts, we can help with that, too. We can also help you run a cost/benefit analysis to see if an on-site parts inventory makes sense. Contact us here, or request a quote for a specific job.