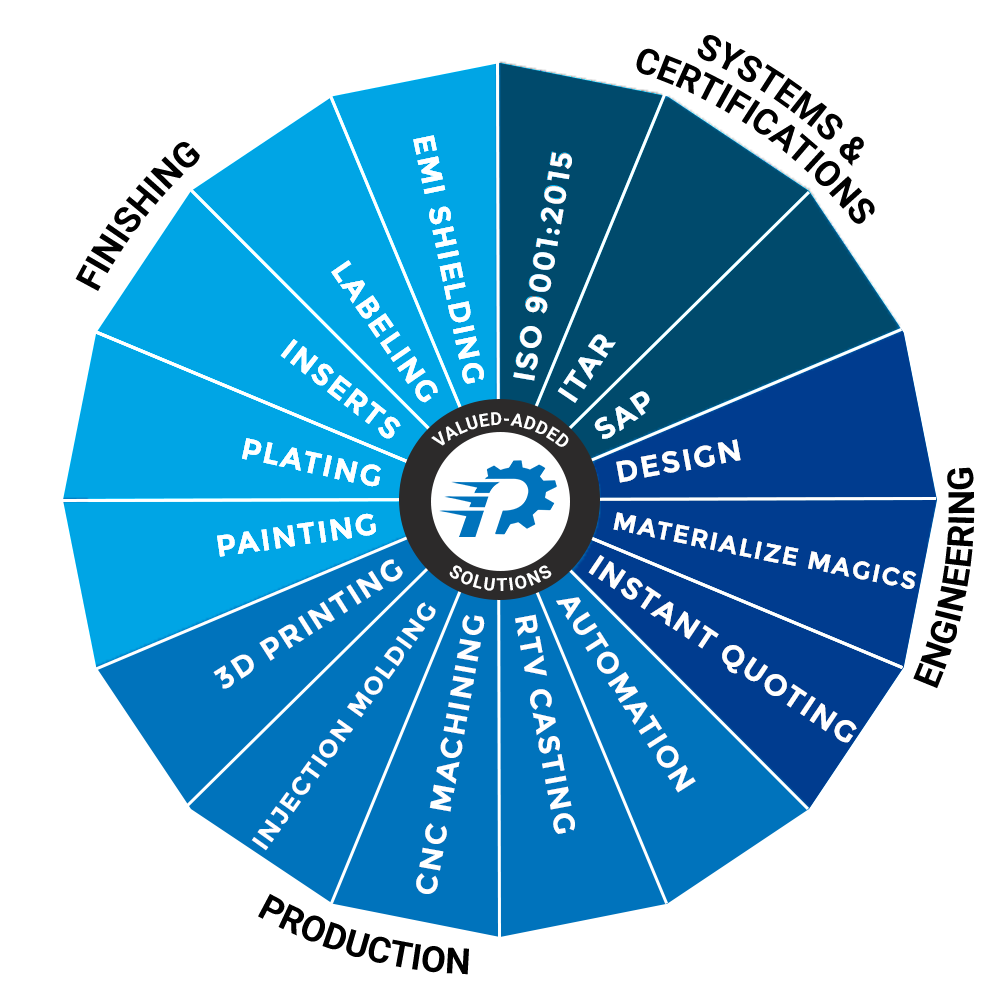

Here at ProtoCAM, we provide our customers with the highest-quality parts and prototypes, quickly and cost-effectively. We also offer value-added solutions for your 3D printing and additive manufacturing prototype and production products. These solutions span the entire additive manufacturing process, from engineering to finishing, and everything in between, as demonstrated by our ProtoCAM Polygon of Solutions:

Our value-added solutions start before the manufacturing process even begins with our top-of-the-line systems and certifications. We utilize SAP Business One business management software, which helps to streamline our key business functions and human relations operations so that when customers request quotes and place orders, their experience is organized and seamless. Our ISO 9001:2015 certification and ITAR registration ensure responsible manufacturing as well as continuous improvement and maintained standards at all times within our facility.

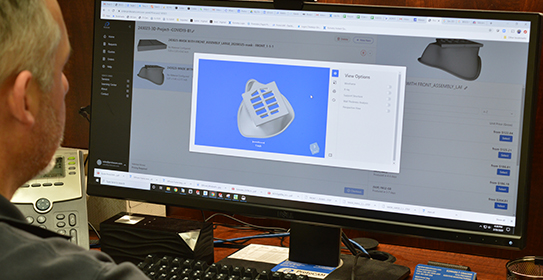

Within the engineering phase of our additive manufacturing processes, we turn to our specialized team of engineers and prototyping specialists and their encyclopedic knowledge of additive manufacturing methods and materials to offer the best design advice to our customers based on unique Design for Additive Manufacturing (DFAM) techniques. Our engineers utilize industry-leading Materialise Magics, the data preparation and STL editing software for additive manufacturing that allows for rapid file conversion and includes repair and editing capabilities to ensure the highest quality STL files are prepared for printing. Our instant quoting platform further streamlines our engineering process by allowing customers to easily acquire quotes and submit orders anytime, anywhere.

ProtoCAM’s value-added solutions further present themselves during the production phase; 3D printing, injection molding, CNC machining, RTV casting, and automation are all processes offered at ProtoCAM in various iterations to provide most any technique a customers might require to bring their unique product to market, and to create their part or prototype to their exact specifications.

Finally, our finishing workshop allows for end-product post-processing to provide our customers with the solutions they require to complete their value-added part. EMI shielding, labeling, inserts, plating, and painting are just a few of our most prominent finishing techniques offered; visit our post-processing and finish levels page to learn about even more options.

At ProtoCAM, we strive to be your one-stop shop for all additive manufacturing services and techniques; our Polygon of Solutions demonstrates our commitment to this goal and represents our continuously improving capabilities to create value-added solutions for all customers.

Ready to Bring Your Own 3D Additive Manufacturing Project to Life?

Request a quote (instant or engineer-assisted) and let us aid you in producing your high-quality parts and prototypes.