Traditional manufacturing involves many individuals working together to bring a product to fruition. Automated manufacturing introduces automated technologies and processes into the mix, which provides many benefits to the end product and the customer.

Automation of additive manufacturing technologies and post-processing is a primary aspect of the Fourth Industrial Revolution, in which breakthroughs in new and better digital technologies are ever increasing. Automated manufacturing contributes greatly to the quality, speed, and cost of 3d printing and additive manufacturing processes, positioning additive manufacturing to continue to surpass traditional manufacturing.

Perhaps the most obvious of benefit of automated manufacturing technologies is the ability to implement consistent quality across multiple part iterations. Automation, as opposed to part handling by individuals, helps to ensure standardized quality with each part iteration. At ProtoCAM, our ISO 9001:2015 certification means we have a commitment to continuous improvement and consistently providing products and services that meet customer and applicable statutory and regulatory requirements. Our processes help to ensure conformity, consistency, and standardization across products, and utilizing automated manufacturing technologies further helps us meet these goals.

Automated manufacturing also helps to speed up production processes and get parts into customers’ hands and out to market faster. Faster printers require faster post-processing to keep up with the speed of production, which is not always possible without traditional post-processing. The automation of post-processing allows for more parts to be finished at the same rate that the latest and greatest 3D printers can print them, thus accelerating the entire manufacturing process.

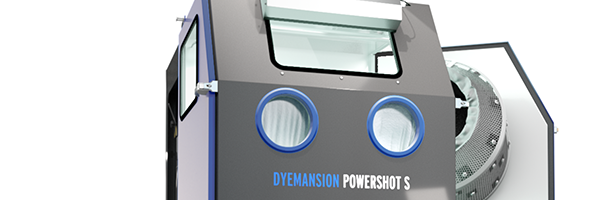

Here at ProtoCAM, we utilize automation technologies like our DyeMansion Powershot S system within our production processes in order to provide production services for products like Fader Plugs, DGH’s Scanmate Flex, and even personal protective equipment. Our automated processes continue to evolve with our customers’ needs so that we’re able to provide the best products possible at the fastest rate.

Implementing automated manufacturing technologies enables us to have higher volume production capabilities and be a more efficient manufacturer, with processes that are standardized to ensure better consistency between parts and allow us to get parts in customers’ hands faster. As always, stay tuned to our news page for the latest innovations being introduced at ProtoCAM!

Ready to Bring Your Own 3D Additive Manufacturing Project to Life?

Request a quote (instant or engineer-assisted) and let us aid you in producing your high-quality parts and prototypes.