What is Selective Laser Sintering?

SLS: Strong, Laser-fused Parts

Selective laser sintering (SLS) is an additive manufacturing process where a laser traces a pattern on powdered material (usually nylon), fusing the material into a solid structure. New powder is applied on top of the hardened material and the process is repeated, adding layers to the part until completion.

SLS is a workhorse technique, best used for applications where mechanical strength is more important than aesthetics. It’s also ideal for creating low-cost, proof-of-concept parts. The sintering process leaves the surface finish slightly rougher than other processes such as stereolithography (SLA) and PolyJet. If you want an impressive finish for product demonstrations, either of these would likely be a better choice.

Get Rugged Performance from SLS Parts

SLS is known for creating tough end products and prototypes, and SLS parts are often used for functional testing. SLS parts have a homogenous material construction, and are therefore strong in every direction. The layer-by-layer sintering process creates uniform strength throughout and across the entire part. In contrast, some other AM methods are strong in one direction and weaker in another due to the material’s grain, similar to a piece of wood.

Choose From A Wide Variety of Materials

SLS parts can be made with a number of of thermoplastic materials, such as nylon, and polyamides. This allows SLS to create products with mechanical properties similar to injection molded parts.

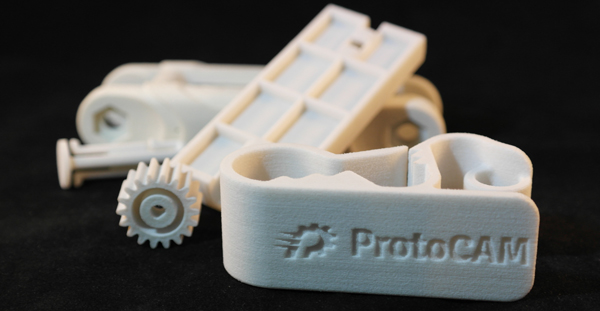

ProtoCAM’s engineers have used SLS to create products as varied as snowboard bindings, complex hex keys, and gear sprockets. SLS is especially good for making rugged, durable parts for use in extreme environments

SLS Materials: A Sampling

- Laser-sintered nylon is heat- and chemical-resistant, and certified for surgical testing or autoclave exposure.

- Laser sintered glass-filled nylon delivers increased stiffness that stands up to extreme conditions.

- Nylon FR-106 is a fire-retardant polyamide that meets the strict Federal Aviation Regulations.

- Duraform EX elastomer has a flexible tear strength that far exceeds that of PolyJet materials.

Typical Results

SLS is excellent for creating resilient prototypes for heavy-duty functional testing, as well as durable production parts. SLS is:

- Strong: SLS materials have mechanical integrity and heat resistance, with some able to withstand temperatures up to 100°C and an electrical charge of 460 amps.

- Test-ready: Tear-resistant and resilient materials stand up to the rigors of functional testing.

- Versatile: Thermoplastics and metal materials allow SLS to meet a wide variety of needs.

- Quick: Turnaround time is as fast as a few days.

- Cost-effective: ProtoCAM offers competitive pricing for SLS parts.

Technical Specifications

The maximum build envelope for an SLS project is 29″ x 15″ x 23″.

- XY tolerance is +/- 0.005″ for all features smaller than 2″, and +/- 0.003″ per inch for all features larger than 2″.

- Z tolerance is +/- 0.010″ in the first inch, then +/- 0.003″ per inch thereafter.

Do you have questions about SLS or other additive manufacturing methods? Contact us here to discuss your next project.