In Fused Deposition Modeling (commonly known as “FDM” or “Fused Filament Fabrication [FFF 3D printing]), parts are produced through the extrusion of thermoplastic materials from spools or wires. FDM is particularly popular among manufacturers who need the flexibility to use engineering-grade thermoplastics like ABS and polycarbonate.

The ProtoCAM Distinction

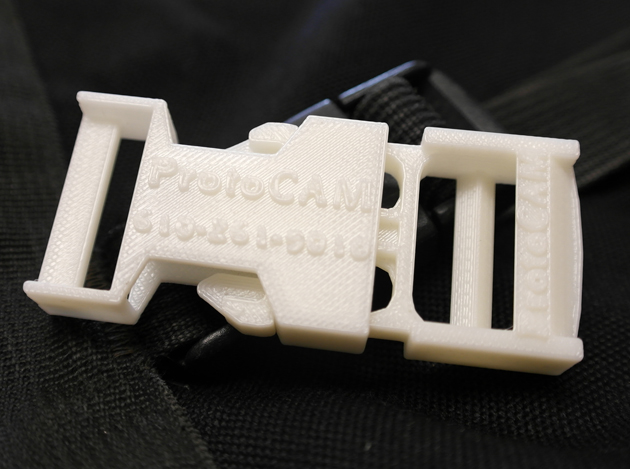

Here at ProtoCAM, we do Fused Deposition Modeling differently. Our experienced engineers work with our customers on their unique FDM 3D printing projects to understand exactly what their goals are and what they would like their end product to be. The ProtoCAM Distinction means that we’re available throughout the entire FDM additive manufacturing process, from initial idea to end product, and we have the capabilities and know-how to guide any project–from prototype to production–to completion.

Your personal project engineer is regularly available to assist you in choosing a material, technology, process, post-processing method, and more, and our friendly customer service representatives can update you on your project timeline, cost, and delivery requirements. Because we’re ISO 9001:2015 certified, you can be assured that your FDM prototypes and parts will be completed according to our high quality standards and produced and delivered to you as quickly as possible, with continuous improvement being a central goal to our facility’s procedures in order to meet our customers’ ever-evolving requirements. Our instant quoting platform means you can order your parts immediately, while our engineer-assisted quoting form allows you to connect further with our engineers on your more in-depth project, and with each order placed, you can be assured that we’re always working towards more sustainable and environmentally-friendly standards of material disposal and recycling, packaging methods, and more.

In offering our FDM printing services, we utilize several large-frame systems produced by Stratasys, which have a build envelope up to 36” x 24” x 36″. Our printers can be used to create small or large detailed, end-use parts that are perfect for form and fit testing, with the ability to utilize multiple post-processing techniques, including smoothing, support removal, bead-blasting, and more. We also offer a variety of materials, including engineering-grade materials; see our Fused Deposition Modeling Material Data list below for more details on all the materials we have available.

Read on to learn all ProtoCAM’s unique Fused Deposition Modeling services, or request a quote now to start experiencing the ProtoCAM Distinction for yourself.

What is Fused Deposition Modeling

Fused Deposition Modeling (FDM), a common additive manufacturing technique, requires two kinds of materials to create a finished product. The process utilizes a support material that acts as a structure for the modeling material that will comprise the final piece or prototype.

In Fused Deposition Modeling 3D printing, an extrusion nozzle lays melted plastic or metal material onto a base/build platform/table in a crosshatch pattern based on coordinates supplied by the 3D CAD file. As each layer solidifies, the base is lowered for the next layer. Support materials are removed by hand once the part comes off the machine, and the part or prototype can then be finished and polished to final spec.

Fused Deposition Modeling Tolerances

The technology has a general tolerance of +/- 0.005″ for 1st inch plus +/- 0.002″ for each add inch.

Need to compare technology tolerances? Click here to view our tolerance comparison chart.

Fused Deposition Modeling in Action

FDM Case Studies & Blogs

As we produce such a wide variety of products and projects for many different markets and industries using our Fused Deposition Modeling technology, we like to showcase all the unique ways FDM can be utilized to create end products and FDM prototypes. Check out some of the below case studies to experience the multi-faceted capabilities inherent with choosing FDM from ProtoCAM!

Testing Materials with 3D-Printed Catapults

Expanded Space + New Printers at ProtoCAM

Auto Industry Additive Manufacturing

Which Additive Manufacturing Method is Best

Automotive Industry Improvements with Additive Manufacturing

Industrial 3d Printing Manufacturing vs. Home Printing

Why Choose Fused Deposition Modeling

The FDM process is excellent for:

High-stress testing

FDM prototypes can endure heat, chemical, and mechanical pressure.

Form and fit testing

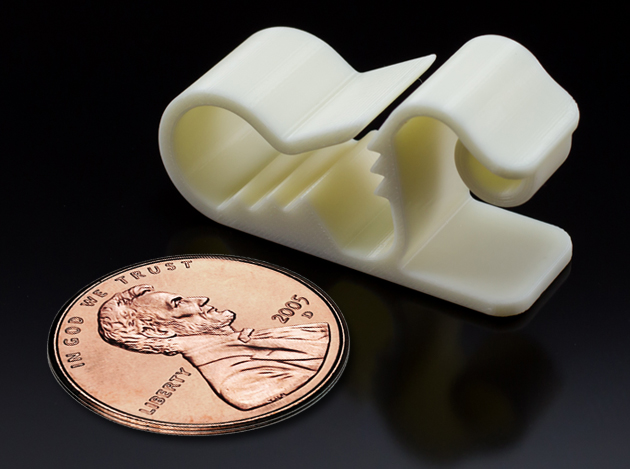

FDM produces highly detailed parts that can be used to test fit and form.

Small, detailed, end-use parts

FDM’s detailed parts can be used in end-use capacities.

Parts made of engineering-grade plastics

ABS and polycarbonate are several of the options available with FDM.

Typical Fused Deposition Modeling Use Cases

| Small-batch manufacturing | Complex geometries | Pieces with open cavities |

| Final-part manufacturing | End-use parts | Click here to see available finishes |